${ formatSectionTitle(diameter) } (${ productsByDiameter(diameter).length } Results)

No products found. Please adjust your search criteria.

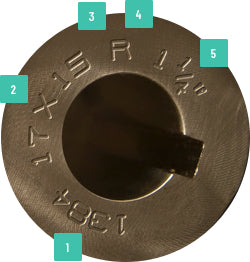

Reading Your ACME Prop

Finding and knowing your ACME propeller’s unique prop number — as well as the technical information that’s found on each ACME prop — makes the process of replacements easier.

- Part Number

- Diameter x Pitch

- Constant/Variable (Sport)

- Left/Right Rotation

- Bore/Shaft Diameter